Historically, twisted pair copper cabling performance was attributed primarily to the cables used. As local area network speeds increased, and the cables improved, other channel components such as connectors started to play a larger role. It became clear that the type of components used in a system could affect the composite performance of the total system (i.e., Category 5E, 6, 6A, 7, and 8 cabling). Performance is also affected by the installation practices, especially the length of patch cords used and the amount of untwist of cable pairs at connection points.

Historically, twisted pair copper cabling performance was attributed primarily to the cables used. As local area network speeds increased, and the cables improved, other channel components such as connectors started to play a larger role. It became clear that the type of components used in a system could affect the composite performance of the total system (i.e., Category 5E, 6, 6A, 7, and 8 cabling). Performance is also affected by the installation practices, especially the length of patch cords used and the amount of untwist of cable pairs at connection points.

CLICK TO TWEET: Involved in the installation of premises infrastructure cabling for Uniprise and NETCONNECT solutions, then CommScope's James Donovan can help.

The “weak link” in a cabling channel is found at the connection points. The twist of the pairs in high-performance twisted pair cables must be maintained during termination up to the point where the individual wires enter a connector or a piece of equipment. While twisted pair connectors are physically interchangeable (one manufacturer’s RJ45-style jack usually fits into another’s faceplate), they do vary in termination techniques. The manufacturers’ documentation provides you the details.

Twisted pair wiring is designed so that the same wires continuously connect from one end of the system to the other. That is, green-to-green, orange-to-orange, and so on, so in this respect, it’s just like electrical wiring.

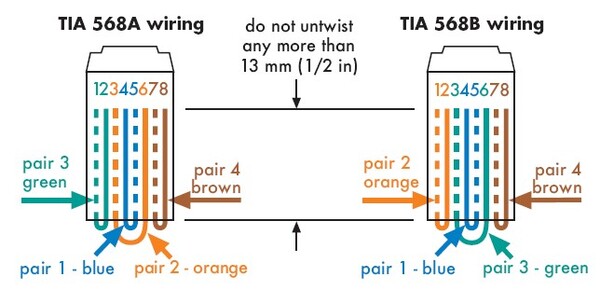

Twisted pair cables typically terminate in one of two schemes that are defined in cabling standards. These are T568A and T568B wiring schemes. Either are acceptable, however, for obvious reasons, it is important that only one method be used consistently throughout the entire network infrastructure. The difference between them is that the orange and green pairs are reversed.

A standard color code allows for quick identification of wire pairs. For 4-pair unshielded twisted pair cables, they are specified by standards, as shown here in this image:

- Pair 1 (blue with white/blue)

- Pair 2 (orange with white/orange)

- Pair 3 (green with white/green)

- Pair 4 (brown with white/brown)

Physical connections in outlets, patch panels, and punch-down blocks, are usually of the Insulation Displacement Connector (IDC) type. The IDC technique depends on the conductor insulation being much softer than the cable conductor, so that it is forced aside under pressure. As a wire is inserted into place, the connector automatically displaces the insulation to permit clean conductor contact and a gas-tight seal of the contact area.

Maintaining conductor twist, especially at terminations, is essential for optimum end-to-end network performance. So, it is recommended not to untwist anymore than 13 mm (0.5 inches). There are many different proprietary tools and methods for ensuring this so always refer to the connector manufacturerss specifications. The normal technique is to use a ring tool to remove about 7.5 cm (0.3 inches) of jacketing to expose the pairs. While preparing them for connectorization, the pairs are separated without untwisting the conductors. The conductors are then placed in the appropriate slots in the outlet module, and seated with the appropriate tool.

CommScope’s SL termination technology provides for fast and reliable terminations using an integrated lacing fixture for use with the SL Series modular jack termination tool.

This is a prime topic in the SP3801 Installing Premises Cabling Systems course, and is a must for anyone looking to get cabling installation right. This certification course teaches the latest installation and termination techniques to support a premises cabling solution to ACT 1 level.

If you are involved in the installation of premises infrastructure cabling for Uniprise and NETCONNECT solutions, then this is the starting course for you.

Additional Resources