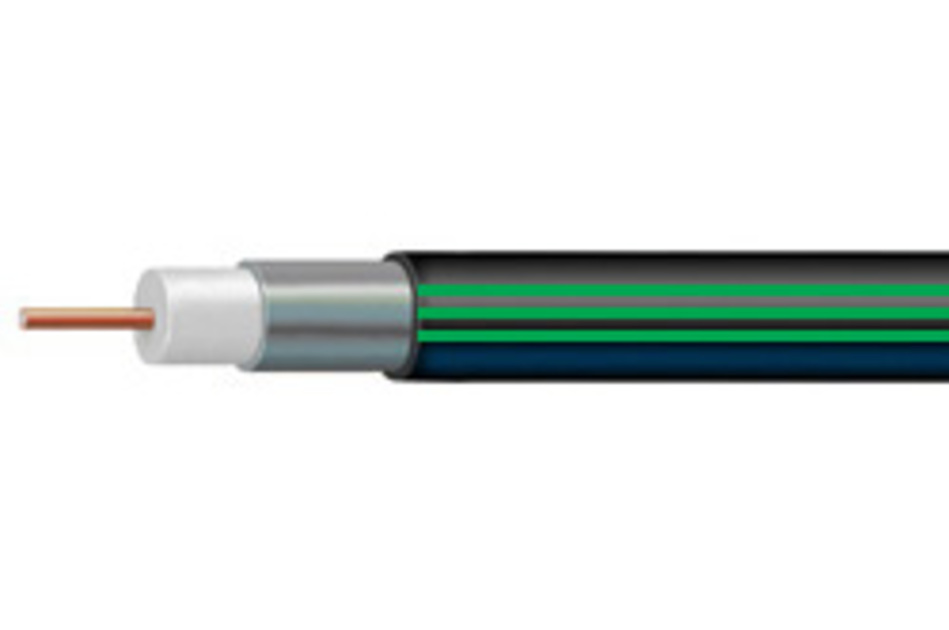

75 Ohm P3® Trunk and Distribution Cable, black PE alternative jacket with three co-extruded green stripes, Build America Buy America (BABA)

Build America Buy America (BABA)*

Rely on CommScope for Broadband Equity Access and Development (BEAD) Program and other government funded projects

Features and Benefits

- *Product complies with the Build America, Buy America Act (BABAA) requirements of the Infrastructure Investment and Jobs Act of 2021 (Pub. L. 117- 58, §§ 70901-70953), or is the subject of a waiver approved by the Secretary of Commerce or designee. Compliance requirements and waiver applicability vary based on government funding program. Check the laws and regulations for your specific program.

Specifications

Product Classification

| Regional Availability | North America |

| Product Type | Coaxial hardline cable |

| Product Brand | P3® |

| Government Requirements | Build America Buy America (BABA) compliant* |

| Warranty | One year |

General Specifications

| Cable Type | 750 Series |

| Construction Type | Swaged |

| Jacket Color | Black with three co-extruded green stripes |

| Location of Manufacturing | Catawba, North Carolina |

| Short Description | P3 750 JCAT 3G AJ SM PR7709 |

Dimensions

| Cable Length | 762 m | 2500 ft |

| Diameter Over Center Conductor, nominal | 4.242 mm | 0.167 in |

| Diameter Over Dielectric, nominal | 17.323 mm | 0.682 in |

| Diameter Over Jacket, nominal | 20.828 mm | 0.82 in |

| Diameter Over Outer Conductor, nominal | 19.05 mm | 0.75 in |

| Jacket Thickness, nominal | 0.889 mm | 0.035 in |

| Outer Conductor Thickness, nominal | 0.864 mm | 0.034 in |

Electrical Specifications

| Capacitance | 50.197 pF/m | 15.3 pF/ft |

| Capacitance Tolerance | ±1.0 pF/ft |

| Characteristic Impedance | 75 ohm |

| Characteristic Impedance Tolerance | ±2 ohm |

| dc Resistance Note | Nominal values based on a standard condition of 20 °C (68 °F) |

| dc Resistance, Inner Conductor, nominal | 1.87 ohms/km | 0.57 ohms/kft |

| dc Resistance, Loop, nominal | 2.493 ohms/km | 0.76 ohms/kft |

| dc Resistance, Outer Conductor, nominal | 0.623 ohms/km | 0.19 ohms/kft |

| Jacket Spark Test Voltage | 5000 Vac |

| Nominal Velocity of Propagation (NVP) | 87 % |

| Operating Frequency Band | 5–3000 MHz |

| Structural Return Loss | 24 dB @ 1003–1218 MHz | 24 dB @ 1219–1794 MHz | 30 dB @ 5–1002 MHz |

| Structural Return Loss, Grade N | ≥24 dB @ 1003–1218 MHz | ≥24 dB @ 1219–1794 MHz | ≥30 dB @ 5–1002 MHz |

Attenuation

| Frequency | Attenuation (dB/100 m) | Attenuation (dB/100 ft) |

| 5.0 MHz | 0.360 | 0.110 |

| 55.0 MHz | 1.210 | 0.370 |

| 85.0 MHz | 1.510 | 0.460 |

| 204.0 MHz | 2.360 | 0.720 |

| 211.0 MHz | 2.430 | 0.740 |

| 250.0 MHz | 2.660 | 0.810 |

| 300.0 MHz | 2.920 | 0.890 |

| 350.0 MHz | 3.180 | 0.970 |

| 400.0 MHz | 3.440 | 1.050 |

| 450.0 MHz | 3.670 | 1.120 |

| 500.0 MHz | 3.870 | 1.180 |

| 550.0 MHz | 4.070 | 1.240 |

| 600.0 MHz | 4.300 | 1.310 |

| 750.0 MHz | 4.860 | 1.480 |

| 865.0 MHz | 5.280 | 1.610 |

| 1002.0 MHz | 5.720 | 1.740 |

| 1218.0 MHz | 6.410 | 1.950 |

| 1500.0 MHz | 7.300 | 2.230 |

| 1794.0 MHz | 8.070 | 2.460 |

| 1800.0 MHz | 8.080 | 2.460 |

| 2000.0 MHz | 8.570 | 2.610 |

| 2200.0 MHz | 9.050 | 2.760 |

| 2500.0 MHz | 9.730 | 2.960 |

| 2700.0 MHz | 10.160 | 3.100 |

| 3000.0 MHz | 10.800 | 3.290 |

Material Specifications

| Center Conductor Material | Copper-clad aluminum |

| Dielectric Material | Foam PE |

| Jacket Material | Alternative jacket PE |

| Outer Conductor Material | Aluminum |

Mechanical Specifications

| Minimum Bend Radius, bonded | 152.4 mm | 6 in |

| Pulling Tension, maximum | 306.175 kg | 675 lb |

Environmental Specifications

| Environmental Space | Aerial |

Packaging and Weights

| Packaging Type | Reel |

| Weight, gross | 391.387 kg/km | 263 lb/kft |

Regulatory Compliance/Certifications

| Agency | Classification |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Product Classification

| Regional Availability | North America |

| Product Type | Coaxial hardline cable |

| Product Brand | P3® |

| Government Requirements | Build America Buy America (BABA) compliant* |

| Warranty | One year |

General Specifications

| Cable Type | 750 Series |

| Construction Type | Swaged |

| Jacket Color | Black with three co-extruded green stripes |

| Location of Manufacturing | Catawba, North Carolina |

| Short Description | P3 750 JCAT 3G AJ SM PR7709 |

Dimensions

| Cable Length | 762 m | 2500 ft |

| Diameter Over Center Conductor, nominal | 4.242 mm | 0.167 in |

| Diameter Over Dielectric, nominal | 17.323 mm | 0.682 in |

| Diameter Over Jacket, nominal | 20.828 mm | 0.82 in |

| Diameter Over Outer Conductor, nominal | 19.05 mm | 0.75 in |

| Jacket Thickness, nominal | 0.889 mm | 0.035 in |

| Outer Conductor Thickness, nominal | 0.864 mm | 0.034 in |

Electrical Specifications

| Capacitance | 50.197 pF/m | 15.3 pF/ft |

| Capacitance Tolerance | ±1.0 pF/ft |

| Characteristic Impedance | 75 ohm |

| Characteristic Impedance Tolerance | ±2 ohm |

| dc Resistance Note | Nominal values based on a standard condition of 20 °C (68 °F) |

| dc Resistance, Inner Conductor, nominal | 1.87 ohms/km | 0.57 ohms/kft |

| dc Resistance, Loop, nominal | 2.493 ohms/km | 0.76 ohms/kft |

| dc Resistance, Outer Conductor, nominal | 0.623 ohms/km | 0.19 ohms/kft |

| Jacket Spark Test Voltage | 5000 Vac |

| Nominal Velocity of Propagation (NVP) | 87 % |

| Operating Frequency Band | 5–3000 MHz |

| Structural Return Loss | 24 dB @ 1003–1218 MHz | 24 dB @ 1219–1794 MHz | 30 dB @ 5–1002 MHz |

| Structural Return Loss, Grade N | ≥24 dB @ 1003–1218 MHz | ≥24 dB @ 1219–1794 MHz | ≥30 dB @ 5–1002 MHz |

Attenuation

| Frequency | Attenuation (dB/100 m) | Attenuation (dB/100 ft) |

| 5.0 MHz | 0.360 | 0.110 |

| 55.0 MHz | 1.210 | 0.370 |

| 85.0 MHz | 1.510 | 0.460 |

| 204.0 MHz | 2.360 | 0.720 |

| 211.0 MHz | 2.430 | 0.740 |

| 250.0 MHz | 2.660 | 0.810 |

| 300.0 MHz | 2.920 | 0.890 |

| 350.0 MHz | 3.180 | 0.970 |

| 400.0 MHz | 3.440 | 1.050 |

| 450.0 MHz | 3.670 | 1.120 |

| 500.0 MHz | 3.870 | 1.180 |

| 550.0 MHz | 4.070 | 1.240 |

| 600.0 MHz | 4.300 | 1.310 |

| 750.0 MHz | 4.860 | 1.480 |

| 865.0 MHz | 5.280 | 1.610 |

| 1002.0 MHz | 5.720 | 1.740 |

| 1218.0 MHz | 6.410 | 1.950 |

| 1500.0 MHz | 7.300 | 2.230 |

| 1794.0 MHz | 8.070 | 2.460 |

| 1800.0 MHz | 8.080 | 2.460 |

| 2000.0 MHz | 8.570 | 2.610 |

| 2200.0 MHz | 9.050 | 2.760 |

| 2500.0 MHz | 9.730 | 2.960 |

| 2700.0 MHz | 10.160 | 3.100 |

| 3000.0 MHz | 10.800 | 3.290 |

Material Specifications

| Center Conductor Material | Copper-clad aluminum |

| Dielectric Material | Foam PE |

| Jacket Material | Alternative jacket PE |

| Outer Conductor Material | Aluminum |

Mechanical Specifications

| Minimum Bend Radius, bonded | 152.4 mm | 6 in |

| Pulling Tension, maximum | 306.175 kg | 675 lb |

Environmental Specifications

| Environmental Space | Aerial |

Packaging and Weights

| Packaging Type | Reel |

| Weight, gross | 391.387 kg/km | 263 lb/kft |

Regulatory Compliance/Certifications

| Agency | Classification |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Documentation & Downloads

Application Guide

Product Compliance Documentation

Product Specification

Warranty

Application Guide

Product Compliance Documentation

Product Specification

Warranty

Other Ways to Browse

BABA/BEAD NTIA Waiver Self-Certification | (login required)

BABA/BEAD NTIA Waiver Self-Certification | (login required)